directory

One, foreword

(1) (1) the establishment of the document indicates that... 1

The objective statement of the report is that... 1

(3) the President's speech... 2

(4) a brief introduction to the enterprise. 3

Ii. Quality credit report.

(1) the concept of enterprise quality... 3

(2) internal quality management... 5

(3) the integrity of the enterprise. 8

On the basis of the quality of the enterprise... 11

(5) product quality responsibility...... 12

(6) quality management risk management... 13

Iii. Conclusion of the report.

One, foreword

(I) preparation of instructions.

(1) declaration: this report is the quality credit report issued by zhangzhou zishan food industry co., LTD.

(2) scope of report: zhangzhou zishan food industry co., LTD.

(3) report time range: January 1, 2016 solstice December 31, 2016.

(4) report data: the data used in this report are from zhangzhou zishan food industry co., LTD.

(5) report release cycle: the quality credit report of zhangzhou zishan food industry co., ltd. is the annual report.

(6) report acquisition mode:

This report is published in electronic form on the website of the group corporation.

Contact: zhangzhou zishan food industry co. LTD.

Address: the village of the village of yancuo town, longhai city.

Telephone: 0595-6657988

Zip code: 363119

(2) the objective statement of the report.

The statement

Issued by the company of "quality credit report, is the comprehensive summary, the company since its establishment, the quality of credit work related data, especially 2016 annual data and working condition, is in the company strictly abide by the relevant state laws, regulations and industry standards, procedures, earnestly implement the enterprise product quality responsibility, establishing mechanisms for quality good faith results in the work.

Report all relevant data and information true, credible, accord with GB/T 22120-22120 "standard of enterprise credit data item" and GB/T 22118-2008 "standard of enterprise credit information collection, processing, and provide", the company responsible for the objectivity of the content of the report and take the initiative to accept social supervision.

Hereby declare.

Zhangzhou zishan food industry co. LTD.

January 24, 2017.

(iii) speech by the President of the group:

Purple mountain enterprise since factory always uphold the "let consumer eat rest assured food" and "no quality of the production is the black sheep of his family behavior" enterprise culture idea, pursue the "quality first" purpose, as the enterprise culture into every level of production and operation activities, into the staff's behavior in the specification, and be firmly established in the practical work:

1, in order to "quality first, integrity-based" quality credit concept, firmly establish the idea of service for the customers and consumers, the good faith management, the good faith starts a career, really do not harm, do not deceive customers and consumers, and consumers to provide quality products and services for our customers.

2. Vigorously publicize the advanced model of "dedicated and honest and trustworthy", and actively guide employees to practice the enterprise philosophy. Through regular training of education and indoctrination, typical guidance and environment edification, supplemented by the perfect enterprise management system, it has strengthened the concept of integrity that employees and the market need to adapt to.

3, from the leadership to staff, everyone will be "quality first, integrity-based" quality integrity concept to carry out to every aspect of production and operation, so as to realize the value of enterprise, enhance the brand image of the enterprise. Quality and honesty are not a matter of time, but a lifetime. In the future, we will continue to carry out the concept of "quality first, integrity text" with the utmost sincerity, and make more contributions to improve the quality and credit level of the whole food industry.

(iv) company profile.

Zhangzhou zishan food industry co., LTD. Was founded in 1996, is a subsidiary of fujian zishan group co., LTD. The company is located in the zishan industrial park, yicuo town, yancuo town, longhai city, fujian province. The main products are canned preserved vegetables, canned fruits and vegetables, and canned mackerel, sardines and other aquatic products.

As an export-oriented enterprises, the company timely adjust management strategy, namely in go all out to do export business at the same time, actively explore the domestic market, the full build "purple mountain" brand series of products, after the market good response. In 2015, the company invested in a new production line of aquatic products, and the technical standard reached the advanced level in the province.

The company always puts the quality integrity construction in the outstanding position, contracts, keeps the credit, innovates the technology, improves the quality, creates the brand, improves the service, enhances the market competition ability. Adhere to put the quality good faith to the enterprise culture, system construction and concrete production quality management work, put forward the "no quality of the production is the black sheep of his family behavior" concept and the quality of "quality first, integrity management; Prevention first, risk control; Safety first, easy to use "quality policy. Companies adhere to the "quality first, integrity-based" quality credit concept, establish a sound from the technical innovation, product research and development, production, storage and transportation, sales, technical services, the whole process of the whole and comprehensive quality management system, to improve the quality of after-sales service, quality prosecution, and the good faith management, strictly implement the product quality and quality integrity responsibility.

"Put forward by the company takes the lead in response to the country with the line, with standard and homogeneity" meet engineering, become meet engineering advocate, canned again in 2016 was named China's top ten enterprises, to be included in the list of the public in 2016, fujian brand products.

Through product research and development, the company continues to innovate. In 2016, the r&d department has developed 42 new products. Set up a new product development team to strengthen the analysis and determination of market demand. We will actively strengthen the formulation of production standards, and in 2016, we will adopt 11 new enterprise standards, and participate in the revision of 6 national standards.

As agricultural industrialization national key leading enterprise, the company will continue along the orbit of agricultural industrialization, give play to the role of driving and radiation, adhere to the environmental protection, organic, health, the quality good faith to the company development strategy, production management, marketing, internal management, and other aspects, to build brand, bigger and stronger enterprise.

Ii. Quality credit report.

(I) enterprise quality concept.

1. Food safety and quality management policy.

Purple mountain food industry company has always pursued "quality first" purpose, uphold the "let consumers eat rest assured food" brand culture idea, and put the idea into all aspects of production and operation activities, into the employees' behavior in the specification.

The quality and safety policy of the company is "customer satisfaction, employee pleasure, product safety, leading healthy food trend, continuous improvement, environmental protection, service society, and forging excellent ecological purple mountain". Definition of quality safety policy:

A. customer satisfaction: satisfying customer requirements is the basic guarantee that customer satisfaction can be achieved beyond customer expectation. Customer satisfaction first is product quality and safety, and then customer's social responsibility, occupational safety and environmental protection. Only when the customer is satisfied, the market can expand, the enterprise has the development potential. All staff should be customer-oriented and customer-oriented, with the aim of quality winning, through production and work.

B. Employee pleasure: enterprise product, key in person. With excellent people, we can have excellent products and excellent customer satisfaction. Any advanced equipment and management method, if no one is fully invested, is useless. To ensure that the rights and interests of employees, for employees to create a good learning, living and working environment of emotional engagement, to achieve efficient, harmonious, and purple mountain purple mountain, quality optimal purple mountain, saving the purple mountain, the innovation of purple mountain.

C. Product safety: food quality and safety is the foundation of the enterprise's life. It is an important symbol to measure the competitiveness of enterprises and also the most concerned issue of the society. Separate prepared food hygiene has not adapt to the demand of the modern food, there is no guarantee that the final consumer food safety, all the staff to establish highly responsible for the sense of social responsibility to consumers, fulfill "let consumers eat rest assured food" brand culture creed, finally realizes the enterprise is confident that consumers at ease, the government trust of purple mountain.

D. Lead the healthy food trend: innovation promotes development, the market decides the future, only constantly changing the concept, constantly pursuing innovation, the enterprise can continue to develop, can lead the trend. We need to constantly introduce healthy, fashionable and safe food to the market, leading the new trend of the food industry and driving the healthy development of the industry.

E. continuous improvement: promoting prevention and continuous improvement, make full use of the company's existing resources, each can improve constantly summarize and mining, down-to-earth, efforts to improve product quality, product safety, enterprise management, environmental protection, occupational health management, increases the chances of satisfied customers and stakeholders, promote enterprise and into every day, continues to develop, implement purple mountain, one hundred strong companies are sug gested for corporate purposes.

F. saving environmental protection: by all the staff in all aspects of the savings, efforts to reduce the various consumption, make our products more competitive, achieve energy conservation and emissions reduction at the same time, reduce the pollution to the environment, protect the ecological environment around us, to create a healthy and comfortable life, learning and working environment.

G. Service society: make healthy, fashionable and safe food and enrich people's material life; In order to accelerate the optimization of enterprise technology upgrading and structure, vigorously develop ecological purple mountain, increase the company's ability to absorb employment, and fulfill the responsibility for environmental protection and social stability; In order to build a harmonious society as the motive force, legal integrity management, protect the environment, strive to ensure the legitimate rights and interests of stakeholders, actively support public welfare undertakings, and realize the social responsibility of enterprises.

H. forging excellence ecological purple mountain: fully promote the standardization, sequencing and institutionalization of purple mountain enterprises, pursue the excellence of various management, and ensure the leading position of the industry; With leading enterprises to promote the common development of relevant industrial chain, vigorously develop recycling economy, forge ecological enterprises and ensure the sustainable development of zishan enterprises.

2. Quality and safety objectives and quality management objectives.

The finished product inspection pass rate is 98%.

Customer satisfaction rate is 95.5%.

The incidence of major safety accidents is 0.

(2) internal quality management.

1. Quality management organization.

To fit of the normal operation of the quality management system, reasonable division in the organization, company personnel to implement optimum combination, by the manager as a quality good faith management, fully responsible for the daily management work of the company.

Company set up quality assurance department, purchasing department, all equipment, ministry of foreign trade, administration department, hr department, hr department, finance department, etc., each department responsibilities clear, the division of labor cooperation, common to complete the company's quality good faith management, ensure the quality integrity management system effective operation and continuous improvement, quality good faith to achieve goals.

The company establishes the quality policy and the quality integrity goal, the personnel, the plant, the facility and the equipment can guarantee the realization quality policy and the target condition. Established the independent quality credit management system and related system, set up the quality management department, the production management department and so on the management organization, has clarified each department and the corresponding management personnel's responsibility.

The company's quality control department has a veto power, and no department or person has the right to interfere with the quality assurance department. The quality management organization shall have the staff responsible for the quality management of the company. The quality control department is equipped with physical and chemical inspection, microbiological inspection, pesticide residues inspection, packaging material inspection and on-site quality control. Responsible for the inspection, control, supervision and management of raw materials, semi-finished products and finished products.

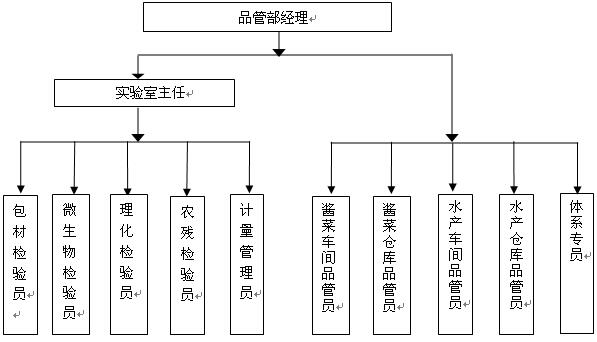

Attached: quality management organization chart.

2. Responsibilities of quality management organization.

(1) organize and formulate the development plan and annual quality work plan of the quality system, and organize the implementation;

(2) organize, improve and review the quality department management system and work flow, and standardize the operation of quality assurance management;

(3) organize the implementation and import of the quality management system, and implement the audit and certification work of the quality management system;

(4) to be responsible for the allocation of inspection and quality assurance resources to meet the quality and ensure the effectiveness of the operation of the system;

(5) organizing internal quality audit;

(6) strictly supervise the work of laboratory work and on-site quality control and prevent unqualified products from entering the market.

3. Quality management system.

Company according to GB/T22000-2006 "quality and safety management system, the requirements of all kinds of tissues in the food chain" IFS, and international food standards, the BRC standard for global food safety standards and the requirements of HACCP system and HALAL HALAL certification standard and canned products and pickles products of the company production and operation of actual quality and safety management system is established, request the company departments earnestly study, implement and update when necessary, in order to continuously improve its effectiveness.

The company applied the principle of process method in the planning of quality safety management system, and considered the following requirements:

A) identify the processes required by the company to produce safe food and its application in the company. And determine the sequence and interaction of these processes;

B) to identify, evaluate and control the quality and safety hazards associated with the product within the scope of the system, so as to avoid direct or indirect harm to consumers by the company's products;

C) determine the criteria and methods required to ensure the effective functioning and control of these processes;

D) to ensure that the reasonably expected and product-related food safety hazards are identified, evaluated and controlled within the scope of the system so as to avoid direct or indirect harm to consumers by the company's products;

E) communication of appropriate information related to product safety throughout the food chain;

F) within the company about the quality and safety management system to establish, implement and update the necessary information communication, to ensure that meet the GB/T22000-2006 "quality and safety management system - requirements for all types of organizations in the food chain" IFS, "international food standards, the BRC global food safety standards and from the system, ensure the quality and safety;

G) monitor, measure and regularly evaluate the quality safety management system and update it when necessary to ensure that the system reflects the company's activities and contains up-to-date information on the quality and safety hazards that need to be controlled.

The processes required for the company's quality safety management system include processes related to management activities, resource provisioning, product planning and implementation, and validation, measurement, analysis, and improvement.

There is no outsourcing process for the quality safety management system.

The quality of the company safety policy is the company's management objective, is to ensure product safety commitment, is the company's quality and safety management, from the first to provides a framework for the establishment of company quality and safety goals. Should pass the slogan, documents, meeting, training and other forms of propaganda and the quality of the public company security policy, outsiders can get, make the company internal departments and personnel to know and understand its meaning. Review the suitability of the management review and modify it when necessary.

(3) enterprise quality and integrity.

1. Quality integrity management.

(1) the integrity of employees education.

In order to firmly establish the integrity awareness of all employees, the company has formulated this annual quality integrity education training program at the beginning of each year. According to the requirements of the company, the head department of each department will prepare education training plan and content, and carefully organize education training. Each workshop director is responsible for the team leader and staff's integrity propaganda education work. Company posted or communicate through special training, the written word, advanced quality good faith staff exchange of experience, the use of early meeting or briefing, using a variety of ways such as the pictures show the enterprise staff quality good faith education. Company to excellent results in the quality good faith education training personnel to offer certain reward, through training on the job after play an exemplary or outstanding grades also give a reward to employees, at the same time in the staff publicity and promotion experience. For employees who fail to participate in the quality integrity education training or fail to pass the training assessment, they shall be given a certain punishment.

(2) product design integrity management.

Enterprise product design and development of strictly according to the design and development control procedures, from food research and development, process all kinds of active record, summarize the development process, management control for examination and assessment of the whole process of food research and development related.

(3) purchase integrity management of raw and auxiliary materials.

The company signed "quality assurance commitment" and "integrity commitment letter" with relevant enterprises providing raw materials. Enterprises to evaluate the supplier according to purchasing products category, when purchasing purchasing department to determine the qualified supplier list, issued a "supplier evaluation", the quality of supplier products, availability, equipment capacity, transport capacity, the delivery price, the quality management system, personnel quality, etc to investigate evaluation, personnel sent to the supplier when necessary factory on-the-spot investigation and evaluation. The supplier list evaluated by the purchasing supply department is officially qualified as a qualified supplier after approval by the general manager. The purchasing supply department shall meet the qualified supplier once a year for one review and the qualified supplier shall be the qualified supplier for the next year. For materials to the factory, the quality assurance department organization personnel for inspection for incoming goods, in addition to the number of incoming goods, packing, appearance outside waiting for validation, quality assurance department of the material should also be according to the incoming inspection plan for validation.

(4) good faith management in the production process.

The production department is responsible for the production process planning and control, according to the production instructions, according to the production process flow chart, various process CARDS, work instruction, organize the production workshops to implement production and control.

The equipment maintenance department is responsible for the installation, maintenance and maintenance of the equipment in the production process, and the maintenance and maintenance of production equipment, as well as the production equipment maintenance plan.

The quality assurance department is responsible for formulating inspection specifications and organizing inspectors to monitor and measure products.

The purchasing department is responsible for the procurement of equipment, process equipment and other materials.

The production department shall prepare the production plan for the approval of the factory department and supervise the implementation.

The personnel department is responsible for organizing and implementing the operation of key processes and training of data analysts. , after the workshop focused on training and shift to the operating personnel to conduct a comprehensive job skills training, hold relevant certificates, and carries on the inspection, the inspection in many ways, enhance staff quality consciousness, improve the level of operation.

Each production workshop is responsible for the control of the production process. In the process of production, management personnel at all levels strictly perform management functions, timely check and correct mistakes in time to ensure the stability of production order. Required for production of raw materials, auxiliary materials, packaging materials for review before feeding, the good quality of the intermediate products and finished products, strict enforcement of "not producing nonconforming, not receiving nonconforming, not circulation of nonconforming product" of the "three principles", the key working procedure quality control point, supervise staff do a good job in self-inspection, mutual inspection, verification procedures, perform monitoring batch records management discipline, strictly do recipients, issue and check the unity. The material balance shall be carried out for each production step to ensure that the input of materials and the output quantity of the products are consistent with the process requirements, and there is no potential quality hidden trouble, which meets the registration requirements.

(5) after-sale quality management of products.

The company establishes a perfect marketing service management system, the sales department sets up full-time after-sales service staff, and sets up a service hotline. The sales department of the company is responsible for the management of the after-sales service information file, according to the detailed classification and archiving on time and regularly.

2. Construction of enterprise quality culture.

(1) safe production management.

Measures to establish safety management institutionalized, standardization, and safety management system, work standard to my company set up safety management organization, set up production safety committee, has been clear about the full-time safety management personnel, security project meetings on a regular basis.

Companies according to their own characteristics make the use of special equipment management system, including homework personnel training education system, maintenance system, hidden perils in daily inspection system, management system, safety meeting system, file management system, regular inspection system, special equipment system of energy saving and emission reduction, safety objective management system, subject to security inspection management system.

Through close cooperation with the government safety management department and fire department, the company carries out the safety policy of "prevention first, prevention and elimination". This paper puts forward the propaganda slogan of "hidden dangers in the open fire, prevention is better than disaster relief, responsibility is heavier than taishan". Through constant publicity, the concept of safe production is carried out to every employee and deeply rooted in the hearts of the people.

The company has set the goal of safe production management, decomposed into various departments and carried out strict assessment. The safe production responsibility system from the President to the staff was developed. Through the development of "safe production month", improve the staff safety production quality.

(2) environmental protection management.

Enterprises always attach importance to environmental protection and sewage treatment. The company has the advanced sewage treatment center, the sewage treatment, all the drainage indicators to meet the national regulations; The clean production has been inspected and accepted by the environmental protection bureau of longhai city, and has obtained the emission pollutant permit.

(3) labor protection management.

In order to strengthen the labor protection of the worker, the company to promote the safe production, maintaining the order of the company's production, to ensure the safety of the worker's personal safety and the property of the company, formulate the corresponding labor protection system; To issue labor protection articles, and set up the personnel health management regulations, at least once a year for all employees.

(iv) enterprise quality basis.

1. Product quality standards.

Our products mainly include: mackerel, sardines, tuna, such as canned seafood, canned coriander heart, canned bamboo shoots, canned vegetables, such as canned litchi canned pineapple canned fruit and pickles, edible fungus products and other products.

Canned seafood, canned fruits and canned vegetables with relevant national product standards (QB/T1375 canned fish, GB/T13207 canned pineapple, QB/T1380 tropical and subtropical fruit canned, QB/T1406 canned bamboo shoots, QB/T4626 coriander heart canned), pickles and edible fungus products perform enterprise standard (Q / 0003 s - 2016 ZZZS sauce pickles).

Enterprises to participate in the revision of QB/T 1406-2014 canned bamboo shoots, canned food inspection QB/T 1006-1006 rule, QB/T 1375-2015, canned fish, shellfish, QB/T 1374-1374 cans, QB/T 4631-2014 canned food packing, marking, transportation and storage, canned coriander heart QB/T 4626-4626, GB/T 13208-2008-7 items such as canned asparagus revision. The company was awarded the China standard innovation contribution award in 2013. Lin dong, director of the enterprise r&d center, is a member of the committee of the third committee of the China food industry association.

2. Enterprise measurement level.

The company has the position of measuring staff, and the special person is responsible for the establishment of the measurement ledger and the inspection of the measuring and calibration of instruments and equipment. Ensure measuring devices, instruments and equipment for product inspection after calibration (qualified calibration service) and effective, exact all quality inspection activities effectively, and through the records of quality activities, ensure its traceability.

3. Certification and accreditation.

The company obtained GB/ t22000-2006, iso22000-2005 certification (certificate no. : 001FSMS1500577) in January 2015, and passed the supervision and verification in October 2016. In January 2015, HACCP system certification (certificate no. : 001HACCP1500020) was obtained and approved by the supervision and verification in October 2016. In November 2014, I obtained the IFS certification (certificate no. : cc-if-132/16) and passed the supervision and verification in November 2016. In April 2016, I obtained HALAL certification (certificate no. ARA-90123596-1705) and passed the supervision and verification in April 2016. In November 2014, I obtained the BRC certification (certificate number: cc-pbr-194/16) and passed the supervision and verification in November 2016.

4. Laboratory testing ability.

The company quality assurance department laboratory undertakes the quality inspection function, has the perfect quality inspection facilities and the equipment. Laboratory, equipped with international advanced testing instruments, with U.S. imports agilent 1100 gas chromatograph, liquid chromatograph, and 6890 uv-vis spectrophotometer instrument, microscope and other instruments, improve the detection means. All inspection personnel have college degree or above, workshop key positions and personnel have been post professional skills, food safety laws and regulations and safety quality system and other professional training and related training in food safety.

(5) product quality responsibility.

1. Product quality commitment.

Company "food production license (serial number: SC11635068101360) in 2016 4 month renewal, have a deadline to April 20, 2021, scope of canned contain (canned seafood, canned fruit, canned) other livestock and poultry, frozen food, quick-frozen food) modulation, vegetable products (pickles, edible fungus products). The company promises according to GB/T22000-2006 "quality and safety management system - requirements for all types of organizations in the food chain" IFS, "international food standards, the BRC global food safety standards, HALAL HALAL system and food related laws and regulations, requirements and customer requirements to establish and implement quality and safety management system, the continuous improvement of the through the company's quality and safety management system development and perfect.

The company promises that the product publicity advertisement, the instruction manual, the label content are consistent with the country approval, the content is true, no false propaganda. My company all products are marked on the package product after-sales service hotline, if consumers in the process of using my company's products found product quality problem or doubt, all can dial our service hotline, the company promises to consumers recommendations can actively enthusiastic feedback, consumers can timely and properly solve the quality problems is proposed.

2. Product recall.

In order to fully and timely call withdrawn before delivery and identified as unsafe product batch, in accordance with the "measures for the administration of food recall and product quality management system requirements, the company establish and maintain the" management procedure of product recall ", and regularly hold product called withdraw drills, and after delivery of the products may be food safety hazards, to notify the relevant interested parties and implement product recall, and keep record. Company through the strict production management and product delivery inspection, resolutely prevent does not conform to the quality and safety of unqualified products delivered to customers and consumers, minimize quality accidents, to establish a good image of the quality of our products, make customer satisfied.

(6) quality risk management.

1. Quality complaint handling: the company establishes the customer satisfaction and complaint management procedure, and continuously improves the service quality and satisfies the customer through the measurement of customer satisfaction. Provide customers with satisfactory service, timely and properly handle customer complaints, and continuously improve product and service quality.

2, quality risk monitoring: to establish the protection plan for process safety, personnel safety and the safety of the water and ice, lab safety, enterprise internal and external, shipping and receiving safety, set up the quality safety and risk control.

3, emergency management, the company set up the emergency preparedness and response control procedures for the possibility of food safety incidents or emergency situations for emergency preparedness and response control measures, to ensure the food safety incidents or emergency situations occur get timely treatment, reduce risk and loss.

Iii. Conclusion of the report.

The construction of quality integrity is the common responsibility of the whole society, and we need everyone's joint efforts. Only the whole food production and management enterprise unify the thought, raises the understanding, the honest management, assumes the enterprise quality safety first responsibility person's responsibility, can maintain the whole image of the food industry. We must join hands to ensure the quality and safety of food and ensure the health and safety of the people. In order to speed up the enterprise credit construction, constantly improve the enterprise integrity construction level; To eliminate the industry reputation crisis caused by a few illegal enterprises, establish a new image of food industry; In order to create a good business atmosphere and a good market economic order, we should make our due contribution to the healthy and orderly and fast development of our food industry.